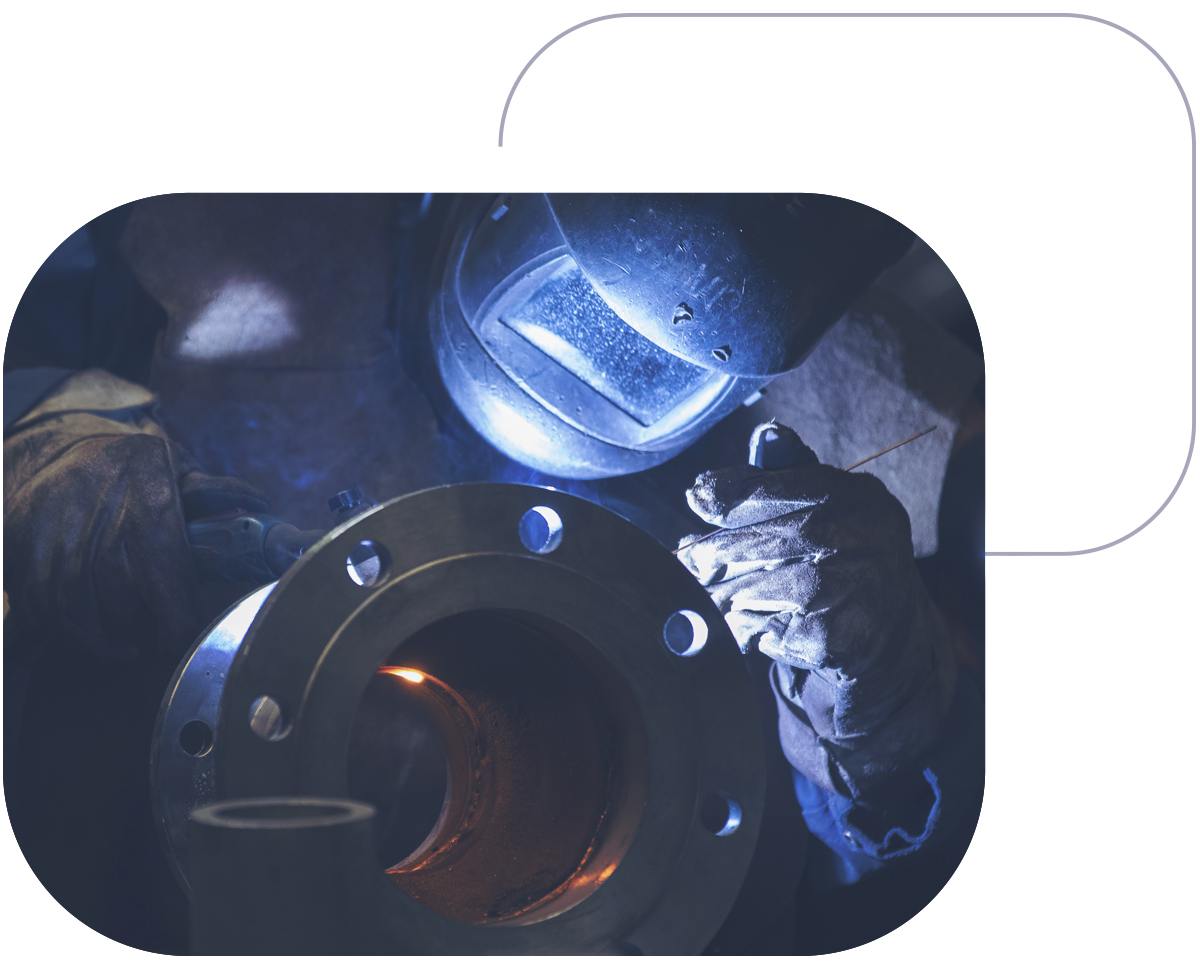

The right people, experienced in what they do, stand behind the entire production process.

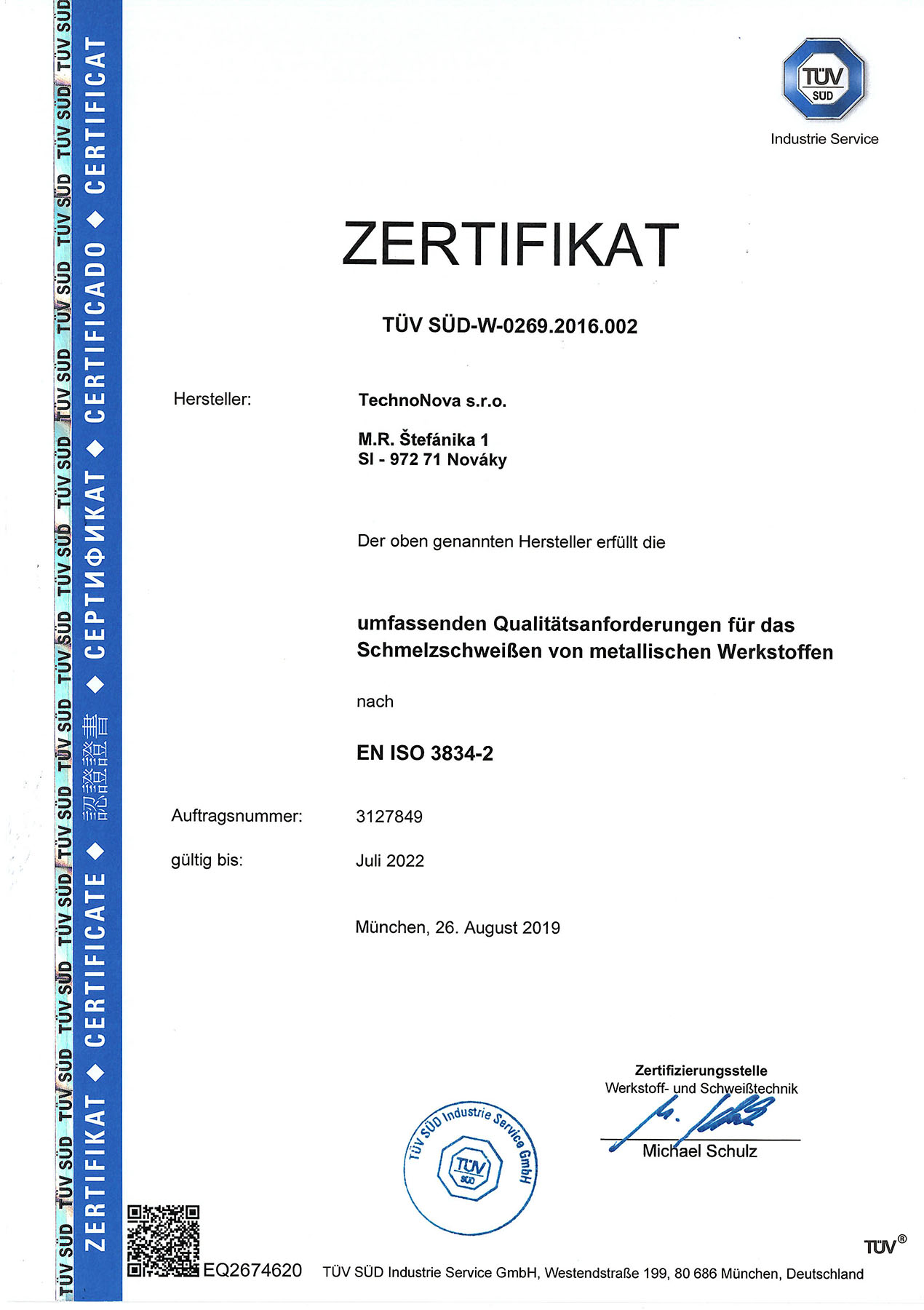

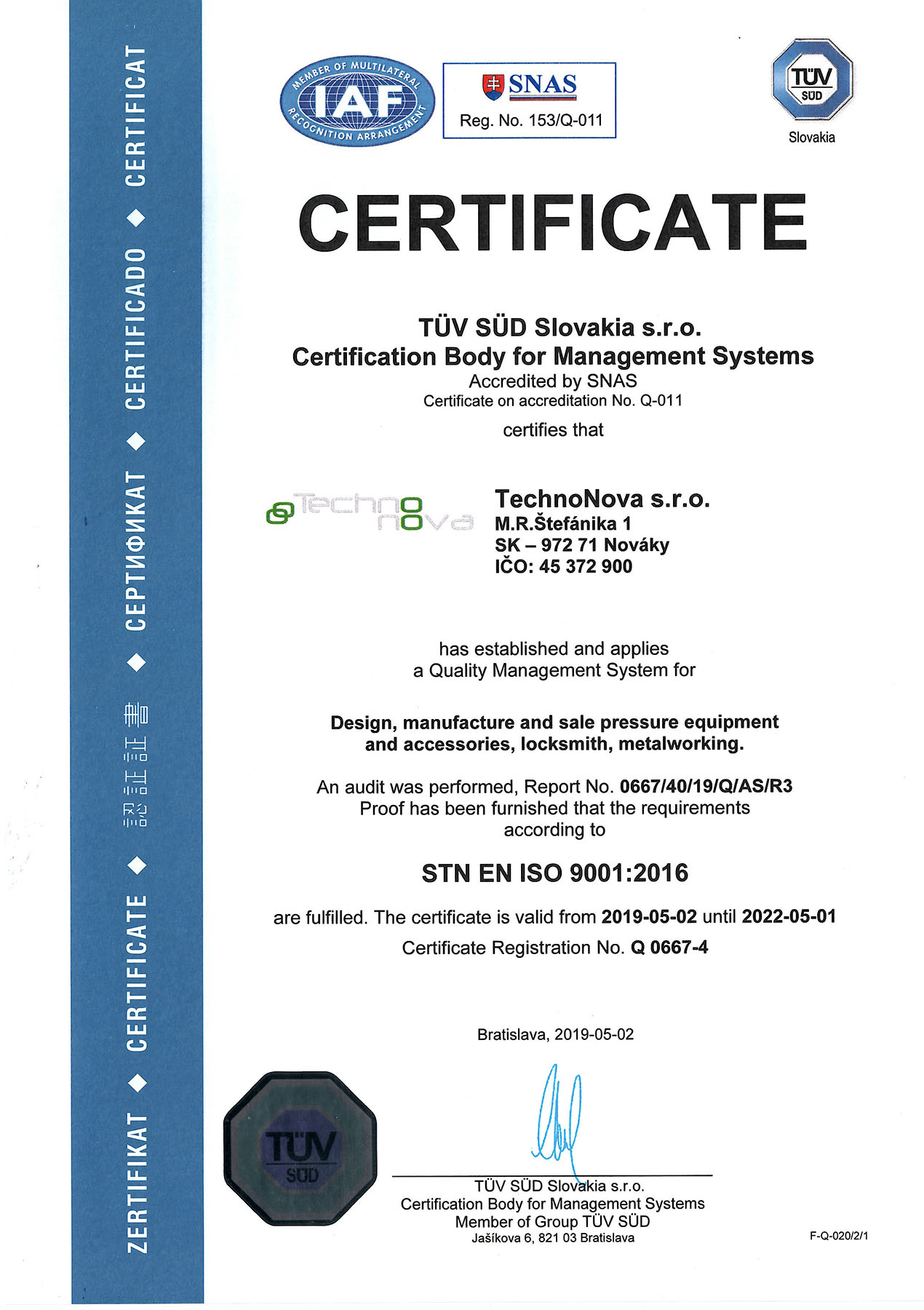

Our welders enjoy many years of experience in their profession. Along with a team of technologists, they form the backbone of the whole process.

Closely cooperating with many companies, TechnoNova is expanding its technological capabilities.

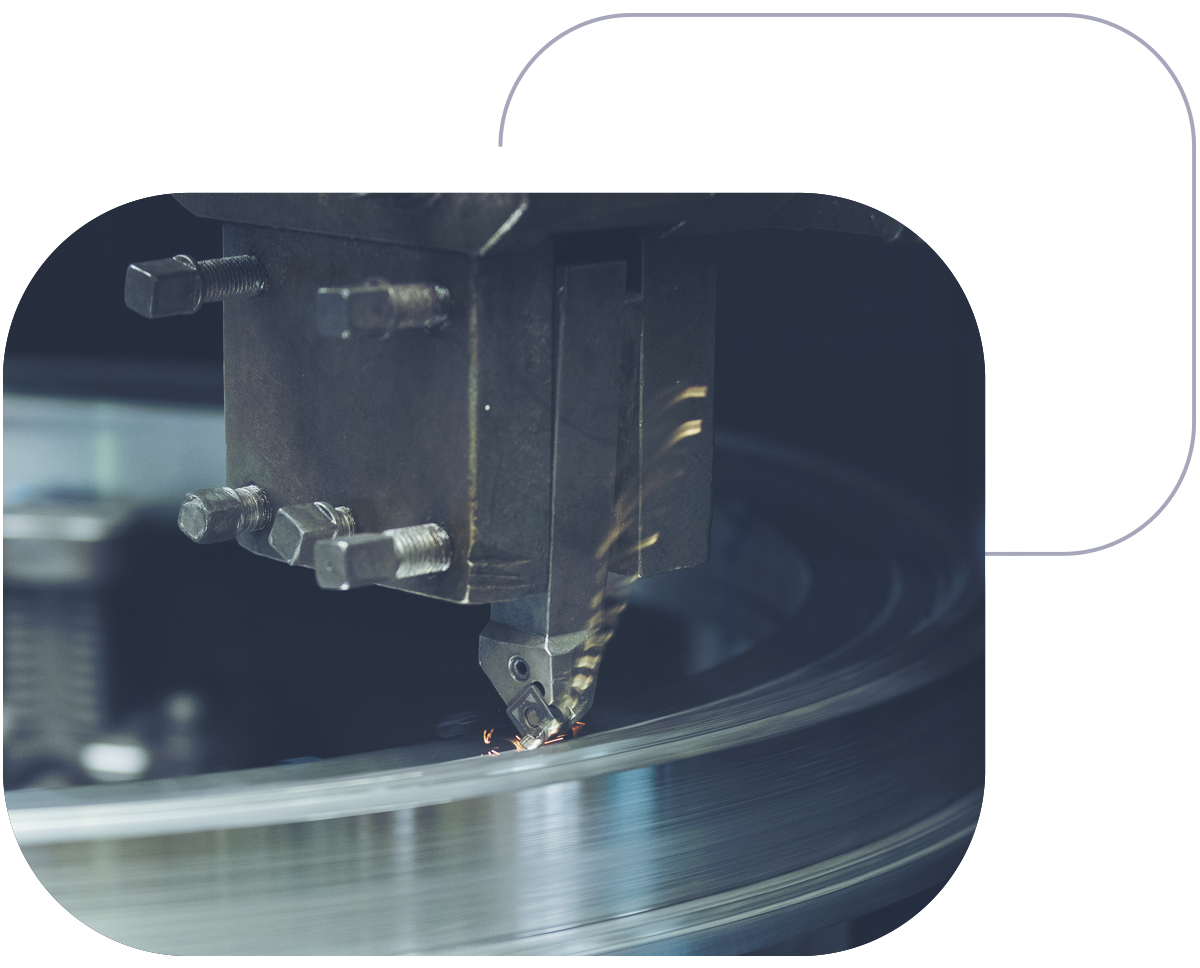

TechnoNova’s technological processes are pushing the boundaries of what the final product can do.

For years, TechnoNova has been manufacturing a diverse range of apparatuses and technology for customers around the world, all of this made possible by in-house experts plus our own technological capacity and production facilities backed with an experienced, professional staff.

We are proud to have end customers using our products in all corners of the world.

NEW - we keep up with current automation trends. We have expanded our technological capabilities with the state-of-the-art ESAB welding machine.